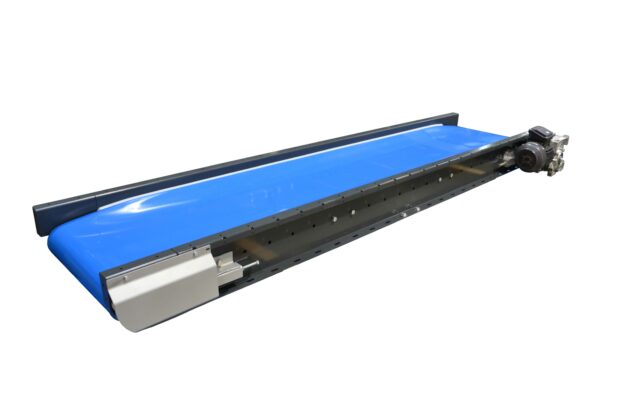

Conveyor transport system are manufactured for one purpose only – to transport products as quickly and safety as possible between individual line elements.

Conveyors always consist of the frame, transversal profiles or rollers for belt support, end rollers and a belt. The belt is moved by an assembly of driven roller, gear-box and electric motor. On request, it is also possible to equipped with a servo-drive or drum motor that offer a higher IP protection. Conveyors are manufactured to be very durable and easy for maintenance.

Besides very wide range of standard models, we are manufacturing custom build conveyors that meet all your needs.

Overview of Htech basic conveyors

| CODE | NAME | DESCRIPTION |

|---|---|---|

| TD* | Transport conveyor | Basic model and the most versatile solution of conveing. |

| PD* | Infeed conveyor | Conveyors designed for feeding packing machines with product. These conveyyors are synchronized with weighers and ensure an continuous dosing. |

| OD* | Take-away conveyor | OD Conveyors are located behind baggers and pick up final packages. |

| CC | Cross conveyor | Cross conveyors are constructed for connecting weighers and packing machine. These conveyors can be reversible, or it can be part of an assembly – PCS |

| RDR | Chain conveyor | Solution for conveying pallets and big boxes. |

| VD | Roller conveyor | Roller Conveyors transport boxes, bins or crates so they can be stacked onto pallets |

| DP | Web conveyor | Web Conveyors allow debris or water to fall through the belt, separating it from produce flow. |

| MOD* | Modular conveyor | Modular conveyors are universal option for transporting produce around corners |

| DZ | Flume conveyor | Flume systems are very gentle on the crop as the produce is dropped into water rather than onto a surface |

*Conveyors can be manufactured in flat or incline design

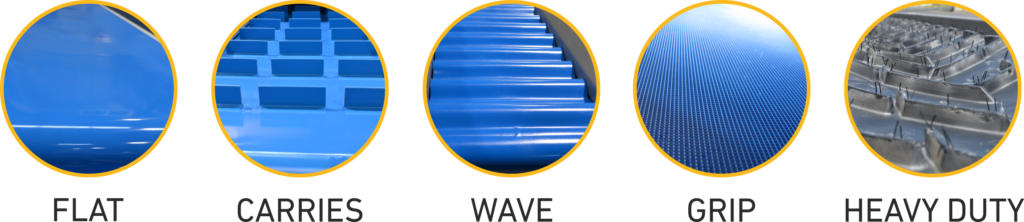

Conveyor belt can be in different colour, style and finish